PREMIUM PRODUCTS

Meta Kaolinite

High-reactivity metakaolin

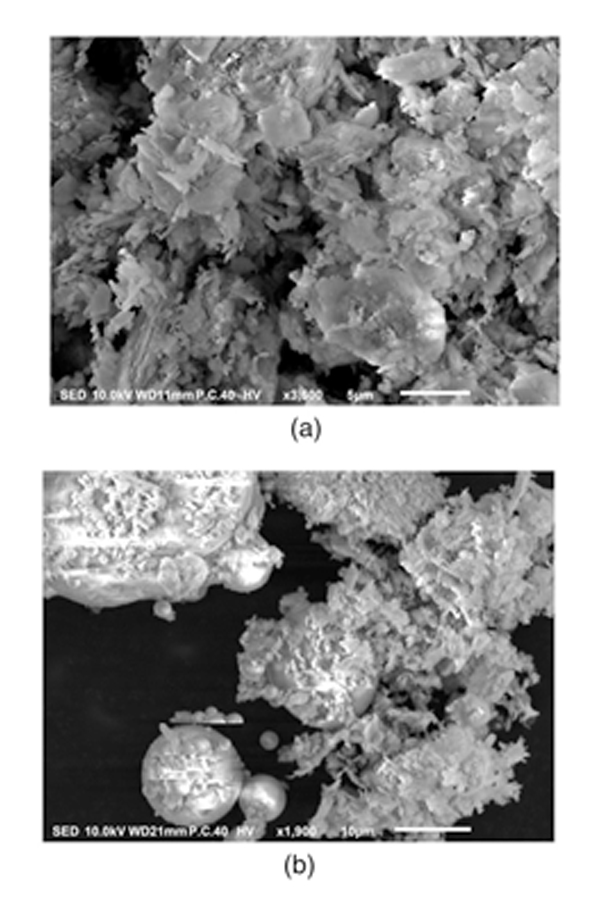

High-reactivity metakaolin (HRM) is a highly processed reactive aluminosilicate pozzolan, a finely-divided material that reacts with slaked lime at ordinary temperature and in the presence of moisture to form a strong slow-hardening cement. It is formed by calcining purified kaolinite, generally between 650–700 °C in an externally fired rotary kiln. It is also reported that HRM is responsible for acceleration in the hydration of ordinary portland cement (OPC), and its major impact is seen within 24 hours. It also reduces the deterioration of concrete by Alkali Silica Reaction (ASR), particularly useful when using recycled crushed glass or glass fines as aggregate. The amount of slaked lime that can be bound by metakaolin is measured by the modified Chapelle test.

Concrete application

Considered to have twice the reactivity of most other pozzolans, metakaolin is a valuable admixture for concrete/cement applications. Replacing portland cement with 8–20% (by weight) metakaolin produces a concrete mix that exhibits favorable engineering properties, including: the filler effect, the acceleration of OPC hydration, and the pozzolanic reaction. The filler effect is immediate, while the effect of pozzolanic reaction occurs between 3 and 14 days.

Adsorption properties

The adsorption surface properties of the metakaolins can be accomplished by inverse gas chromatography analysis.